Today, just 1% of waste is monitored in most materials recovery facilities. Even in advanced economies, 40% of waste sorting is done by hand. In the US alone, that lack of visibility and automation contributes to US$80 billion-US$120 billion a year worth of plastic being lost to landfills and incineration.

Current sampling and sorting methods contend with a lack of data that can lead to lost value, and lower-quality recycled material:

“Today’s technology cannot really detect all the contamination that could be coming with those [materials like] plastics. But if you know what contaminants are coming, there’s a better chance you will be able to process it and get a cleaner product.”

London-based AI waste analytics company Greyparrot have announced a strategic partnership with Bollegraaf Recycling Solutions – the world’s largest provider of recovery and recycling plants – to tackle recycling’s visibility challenge with digitisation and automation.

Meeting the growing waste challenge with data

With global solid waste set to grow to 3.4b tonnes a year in 2050, investment in efficient and accurate sorting infrastructure is urgently needed to avoid exacerbating waste-related pollution and emissions. Greyparrot CEO and co-founder Mikela Druckman believes that digitisation is a vital step towards recovering and reusing more material:

“In a world drowning in waste, a large percentage of which is recoverable, the urgency for action has never been greater. It’s time for a revolutionary leap in how we value, capture, and manage our waste. We’re excited to partner with Bollegraaf to take a significant step in the digitisation of recycling processes”

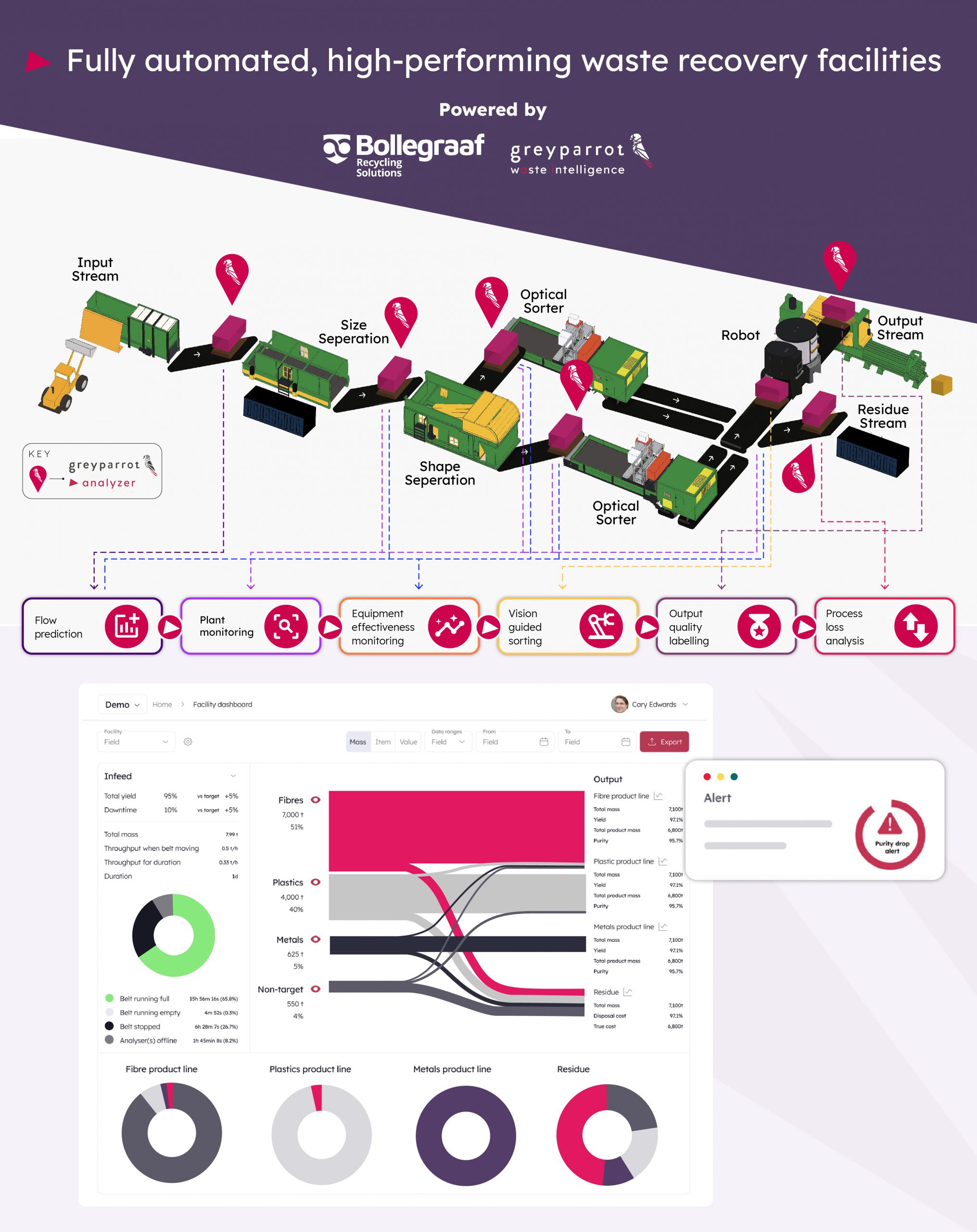

In response, Bollegraaf plans to integrate Greyparrot’s AI waste analytics into its new and existing materials recovery facilities (MRFs) around the world. As Greyparrot’s newest global distribution partner, they aim to speed the sector’s adoption of intelligent automation by making thousands of sorting and recycling facilities more efficient. The technology they’re using to achieve it is already being used to boost recycling rates.

The promise of widespread sorting automation has garnered excitement amongst waste and recycling advocates like WRAP CEO Harriet Lamb:

“Across the world, we need investment in upgrading our waste infrastructure to help drive the circular economy of the future. The partnership between Bollegraaf and Greyparrot will help supercharge the recycling sector, enabling recycling rates to rise thanks to new technology.”

How AI waste analytics boost resource recovery

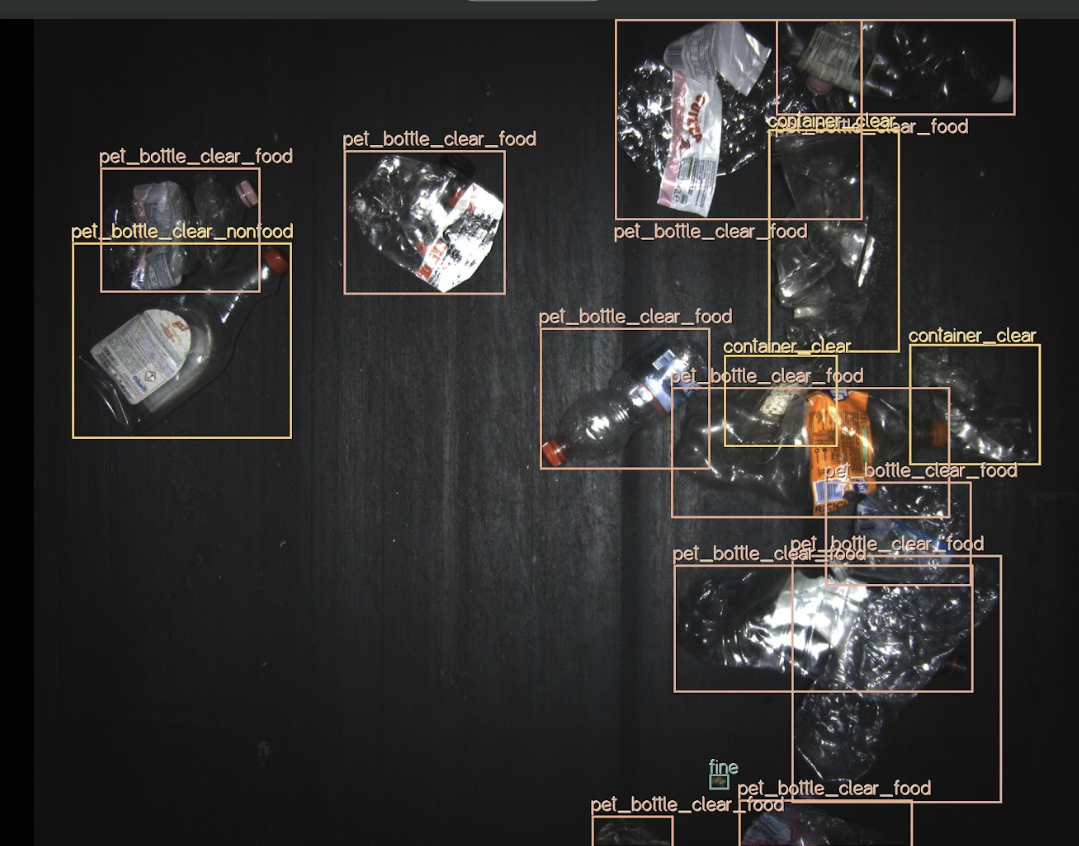

Greyparrot’s computer vision units (known as Analyzers) gather information on waste objects as they pass through the sorting process. They add a detailed digital layer to Bollegraaf facilities, accurately tracking material mass, volume, potential emissions, brand, food-grade status and financial value across 70+ distinct categories of waste.

With automated monitoring, Greyparrot gather detailed data on close to 100% of the material passing through recovery facilities. The technology has already improved recovery rates in 14 countries, where over 100 of Greyparrot’s Analyzers have been adopted, attracting attention from the wider industry:

“Artificial intelligence solutions such as Greyparrot enable collection, sorting and recycling operations to be optimised and digitised for better management and improved performance.”

Greyparrot’s waste intelligence platform creates a live stream of material data that facility managers use to track and recapture resources being lost to residue lines, adjust infeed blends, target sorting processes to frequently-missed materials, and more.

Accelerating digitisation and AI adoption in waste management

With over 50% market share in global recycling plant construction, Bollegraaf’s global reach will mean that AI waste analytics are a standard feature for the next generation of recovery facilities. Leading industry voices like Professor Edward Kosior have been expecting such a development:

“I have always believed that Greyparrot’s innovative technology would one day become the standard for MRF sorting. This partnership with Bollegraaf is poised to make this now happen – at an accelerated pace. This is exciting news for our industry as a whole given that this data will also inform organisations on how to tailor their packaging to optimise recycling efficiency.”

New MRFs designed by Bollegraaf will now feature Greyparrot Analyzers on key sorting lines, but the companies are also looking to retroactively digitise existing facilities.

The increased transparency that comes with intelligence-driven facilities will also help demonstrate compliance with regulatory and contractual requirements. Regulatory bodies like the UK’s Environment Agency are now accepting AI-generated compliance reports that meet their accuracy standards, which suggests that time-consuming sampling and reporting tasks could soon be fully-automated.

Automated, self-adjusting recovery facilities

The companies plan to take data-driven waste management a step further, creating smart systems that dynamically adapt in response to a live stream of waste data.

Greyparrot’s Sync APIs enable them to embed artificial intelligence in hardware and software systems, which plant builders like Bollegraaf can use to build entire sorting operations automatically managed and monitored by AI.

As part of their strategic partnership, the companies plan to co-develop new automated sampling and sorting products to boost recycling efficiency even further:

Capturing the hidden value in waste streams

AI, and the data it gathers in real-time, will help digitise and automate systems to capture a massive amount of lost environmental and financial value.

In 2023, Greyparrot’s waste intelligence insights from 74 global facilities revealed that over a quarter of the average residue line is made up of recyclable plastic, representing thousands of tonnes of potential CO2 emissions and millions of dollars in secondary resources.

Revealing the valuable material currently being lost to landfills and incinerators is a vital first step in the effort to recover it. Greyparrot CEO and co-founder Mikela Druckman had this to say about the philosophy behind the collaboration with Bollegraaf, and the goals of the partnership:

“We have long believed that you can’t improve what you don’t measure. Getting AI waste analytics in the hands of more plant managers, more quickly, will offer the waste industry the data-backed insights needed to build and operate smart MRFs. Collaboration with plant builders and other key players is critical to making this happen, and it’s a major reason why Greyparrot is hardware agnostic, making it possible to integrate our platform with all types of systems.

Progress in addressing the waste crisis can only happen if we work together and commit to systemic change driven by waste intelligence.”

Learn more about the partnership in Greyparrot CEO and co-founder Mikela Druckman’s announcement article.

About Greyparrot

Greyparrot Waste Intelligence for recovery facilities explained in 90 seconds.

Founded in 2019, Greyparrot has rapidly evolved into the leading provider of AI waste analytics. The company has installed over 100 of their Greyparrot Analyzers in recovery facilities across 14 countries (including Biffa, Viridor, Suez, Veolia, KSI, and more), using AI to translate a live stream of images into real-time waste data.

Facility managers use the resulting insights to adjust sorting processes and increase recovery rates, while packaging producers and regulators use their detailed datasets to guide recyclable packaging design and waste policy.

The company’s Greyparrot Sync integrations allow third-party hardware and software developers to embed real-time waste data in their programs, machinery, and across entire facilities.